Heat Balance Analysis in Cement Rotary Kiln

Download Citation | On Jan 1, 2019, Shihab Ali Khalifa and others published Heat Balance Analysis in Cement Rotary Kiln | Find, read and cite all the research you need on ResearchGate.

WhatsApp)

WhatsApp)

Download Citation | On Jan 1, 2019, Shihab Ali Khalifa and others published Heat Balance Analysis in Cement Rotary Kiln | Find, read and cite all the research you need on ResearchGate.

Energy balance Calculate the heat items according to course documentation and fill in the attached sheet "Energy balance of kiln". ENERGY BALANCE OF KILN Specifications Temp. [°C] Energy [kJ/kg cli] INPUT Fuel combustion Primary air: sensible heat Kiln feed: sensible heat Air lift air: sensible heat /*;, .''

Purchase Rotary Kilns 1st Edition. ... Chemical Thermodynamics Gibbs Free Energy and Entropy Global Heat and Material Balance Thermal Module for Chemically Reactive System Mass Balance Inputs Chemical Compositions Energy Balance Inputs ... The Cement Making Process The Cement Process chemistry Rotary Cement Kiln Energy Usage Mineral Ore ...

Dec 24, 2012· article on kiln heat and mass balance – Grinding Mill China 【Key Words】: rotary kiln massheat balance . •Calculation of Kiln Heat and Mass Balance studies, Cooler optimization, Airflow measurements, . calculation of energy balance in cement clinker production in . Mass Balance of a Kiln System Mass Balance .

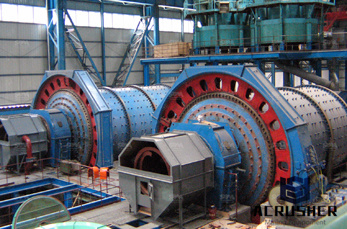

cement kiln heat balance xls sheet BINQ Mining. Dec 21, 2012· heat balance in ball mill – Crusher South Africa. Can anybody send me the Heat Balance excel sheet for Ball Mill and VRM. . drying of raw materials with kiln gas or heat .cement ball mill heat balance . »More detailed. Get Price; cement mill heat balance . Ball Mill Heat ...

Material And Energy Balance For Cement Kiln. Heat balance rotary kiln calculation energy and mass balance for a rotary kiln snap shot of the specific heat heat balance of rotary kiln et price and support online mathematical model for alternative fuel based on a mass and energy balance of a rotary cement kiln gnored in the energy balance.

ANALYSIS OF HEAT LOSS IN KILN IN CEMENT INDUSTRYA REVIEW. ... The energy balance of a rotary kiln used for calcination of dolomite in a magnesium production company identified the kiln .

Heat balance in cement industry is review kiln capacity at the present at the plant comparing with general standard in cement industry or other plants before and after making improvement in order to remove unusual points, unsuitable points, take suitable points but have not been technology limit of expectation of cement field to optimize current system.

Heat balance of rotary kiln It can be seen from the analysis of heat balance test on 1# rotary furnace of China Molybdenum Co., Ltd., that although the two statistics: energy consumption of unit product and quality of production are at the .

In the current environment of energy saving and emission reduction, cement enterprises can start from the following aspects: rotary kiln transformation, waste heat residual pressure utilization, motor system energy saving, energy system optimization, dust removal system transformation and so on.

Heat And Mass Balance In Cement Klinker Kiln Solution. cement kiln heat balance xls sheet Caiman Mining calculation of energy balance in cement clinker production in excel 48 1663 Ratings How to make heat and mass balance of cement kiln mass and heat balance in rotary kiln .

Formula For Heat Balance In Rotary Kiln . How to calculate energy balance on a wet kiln cement nov 02 2012 heat transfer in rotary kilns rbord engineering services co the rotary kiln model being developed encompasses a general mass and energy balance over the process was used to calculate the. More Details

Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energyconsuming and greenhousegas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing ...

heat balance calculation of a cement kiln Solution for, cement kiln heat balance calculation excel sheet Caiman Mining How can i calculate the heat balance in cement Sep 24, 2006 Best Answer: In a kiln there are three zones: The klinkering, the calcining and the preheating zon cement kiln heat balance xls sheet Caiman Mining [Chat Online]

This study deals with the energy audit and heat recovery on the rotary kiln taking a cement factory in Ethiopia as a case system is a dry type rotary kiln equipped with a five stage ...

Heat balance in rotary kiln formulas. heat balance calculation of a cement kiln heat balance rotary kiln calculation greencastproject Modeling of Rotary Kiln in Cement Industry For the balance of power in the rotary kiln the average temperature of the walls was used in To calculate the heat heat balance calculation of a cement kiln,ENERGY AND MASS BALANCE CALCULATIONS

Apr 12, 2016· Join the OPS webinar team for an indepth conversation about Kiln Mass and Balance. Skip navigation Sign in. Search. ... Dryer Design Heat and Mass Energy Balance ... Cement Kiln Refractory Wear ...

Radiation and Convection heat balance in a rotary cement kiln. Pankaj Mandal. ... Energy auditing and recovery for dry type cement rotary kiln systems––A case study. By Tsin Engin. Chapter 14 HEAT Conceptual Questions.

Energy Balance In Rotary Kiln. The rotary kiln at tekumi was commissioned in february 2002he process involves burning limestone at 1000 11 000 c to produce a burnt lime cao producthis paper describes the design and installation of a trifoil system to improve the energy efficiency of.

Jul 09, 2009· Heat Balance. Hey Friends; Since long time i am trying to find the complete calculation of the kiln system heat balance in the books and documents but till now i couldn''t find anything. I will apraciate anyone could send me the calculation of kiln heat balance. thanks. Reply. Know the answer to this question?

mass and energy balance in cement kiln. clinker burning process from when kiln meal is fed into a cyclone preheater to discharge of the clinker from the cooler It is based on energy and material balances and consists of individual models for the plant components namely preheater calciner gas offtake bypass rotary kiln and grate cooler The models are linked mathematically to one

Cement kilns are the most common users of hazardous wastes as blending fuels. Cement kiln energy recovery is an ideal process for managing certain organic hazardous wastes. The burning of wastes or hazardous wastes as supplemental fuel in the cement and other industries is not new.

We choose the parameters to establish rotary kiln process model from some balance of cement production, material balance, gas balance, heat balance, to further improve the production technology efficiency and stability of rotary kiln.

Mass Balance of a Kiln System. The following diagram illustrates an example of the mass flows in a cement plant and the mass balance of a kiln system from raw meal (RM) to clinker. ... Cement CO 2 and Energy Protocol, Internet Manual, created ...

WhatsApp)

WhatsApp)