Why stainless steel corrodes | Nature

The specimen was type 316F stainless steel (a highsulphur steel with a rich inclusion content; a sample with certified analysis was used; see Table 1) polished finally with µm Al 2 O 3 or 0 ...

WhatsApp)

WhatsApp)

The specimen was type 316F stainless steel (a highsulphur steel with a rich inclusion content; a sample with certified analysis was used; see Table 1) polished finally with µm Al 2 O 3 or 0 ...

MPP is a pioneer in volume production of aluminum products. At MPP, we have more than a half a century of experience working with steel, iron, and stainless steel materials.

Manganese Steel, Stainless Steels FluxCored Arc Welding Manufacturer offered by Poona Migweld Private Limited from Pune, Marashtra, India ... View Complete Details. Yes, I am interested! Wear Resistant Fused Alloy Steel Plate. ... the aspiration process, or the powder metallurgy process, or metal injection moulding process. ...

This industrial directory contains a broad range of Castings: Nickel Silver companies serving all industries. This premier and trusted vertical directory contains manufacturers, distributors and service companies giving access to all their information available on the internet.

The " Black 1065 Manganese Steel Tactical Drop Point Tanto w/Kydex Sheath is a very solid heavy duty knife that will attack pretty much anything you throw at it or throw it at. This awesome knife measures in with a 6MM thick blade that''s differentially hardened and hand sharpened. It is a perfect blend of the ancient traditions with modern tactical needs giving you the best of both worlds ...

Parkerizing, bonderizing, phosphating, or phosphatizing is a method of protecting a steel surface from corrosion and increasing its resistance to wear through the application of a chemical phosphate conversion is usually considered to be an improved zinc or manganese phosphating process, and not to be an improved iron phosphating process, although some use the term ...

Steel Steel Wearresistant steels: Another group is the wearresistant steels, made into wear plates for rockprocessing machinery, crushers, and power shovels. These are austenitic steels that contain about percent carbon and 12 percent manganese. The latter element is a strong austenizer; that is, it keeps steel austenitic at room temperature. Manganese steels are often called ...

Dec 17, 2019· Iron or manganese oxide – to adjust the fluidity and properties of the slag and to help stabilize the arc; Iron powder – to increase the productivity by providing extra metal to be deposited in the weld. The principal types of welding electrode coatings for mild steel and are described below.

VWR Collection Providing a Wide Selection of Vials VWR supports you in your autosampler vial selection process through onsite consultations ... Sklar Surgical Instrument Cleaning Brushes From a wide assortment of cannula cleaning brushes to nylon and stainless steel instrument ... > Manganese ≥%, Powder. Manganese ≥%, Powder

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical manner by the use of jigs .

Manganese Ore Extraction Process By Jig Manganese Bog Ore, Iron Ore Concentrate, Iron Ore, Manganese Powder, Manganese Atomic Mass, Manganese Rock, Manganese Steel ...

Ramesh Singh, in Applied Welding Engineering (Second Edition), 2016. Killed Steel. Killed steel is deoxidized to such an extent that there is no gas evolution during solidification. Aluminum together with ferroalloys of manganese and silicon is used for deoxidation. In some applications, calcium silicide or other special strong deoxidizers are also used.

As an extension of our Guide to the Best Knife Steel, we''ve compiled the reference table below showing the most popular types of knife steel and their composition of the various elements. You can click on the column to sort the data accordingly. >>See knives with our favorite premium steel at BladeHQ<< Below the table you''ll find a summary of the most commonly used elements in steel ...

Though standard Black Oxide is set up for steel, it can be done on other substrates including stainless steel, copper, and brass among others. ... is an immersion process by which small crystalline structures of iron, zinc or manganese are ''grown'' on steel alloys. There are three main types in use: Iron, Zinc, and Manganese.

Roomtemperature and hot blackening solutions for finishing stainless steel parts. Available in gels, liquid concentrates, and readytouse liquid solutions. ... and convenient inhouse and even athome blackening. Use a roomtemperature blackening process to give steel parts satiny, greyblack finishes. ... Versatile powder solution used to ...

Material properties. Mangalloy is made by alloying steel, containing to % carbon, with 11 to 15% manganese. Mangalloy is a unique nonmagnetic steel with extreme antiwear properties. The material is very resistant to abrasion and will achieve up to three times its surface hardness during conditions of impact, without any increase in brittleness which is usually associated with hardness.

Following hot working, steel goes through a "pickling" process. Pickling is a chemical process whereby steel is run through a progressive series of tanks. Chemicals in the tanks remove oxidation and impurities from the surface of the product. Hydrochloric acid is a common chemical compound used in pickling.

Feb 14, 2020· Global Manganese Ore news, Manganese Ore prices and expert analysis ... Welcome to Fastmarkets now incorporating Steel First. All Steel First prices, news and market analysis can be found here on ... Stainless special steel; Base metals. Latest analysis. LME WEEK 2019: Copper fundamentals and forecast.

Dec 29, 2011· And what about stainless steel? Developed before World War I, stainless steel used in firearms isn''t really stainless. It is very rustresistant, howeverâ€"not because there is so much chromium but because the chromium on the surface reacts to air to form a passive layer of chromium oxide, which seals the iron from oxidation.

Manganese has similar effects like carbon, and steel producers use both of these elements to achieve a material with preferred properties. Manganese is required for the hot rolling process of steel by combining it with sulfur and oxygen. Steels often include % manganese, but certain carbon steels can include up to % of manganese.

In order to produce high manganese steel by the powder metallurgical process, three kinds of Mncontaining powder, that is, electrolytic manganese powder, FeMn alloy powder and FeMnC alloy ...

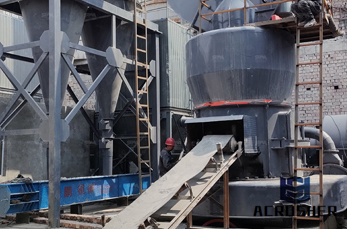

Iron Ore Manganese Ore Processing Technology Energy Saving

Stainless steel, also known as chromium steel or corrosionresistant steel, is a steel alloy made up of at least % chromium. The percentage of chromium in regular carbon steel is much lower. Its other main elements include: carbon, nickel, molybdenum, copper, manganese, titanium, nitrogen, silicon and .

Oct 31, 2012· Manganese is mainly used for steel and iron, manganese in stainless steel is harmless to the human body, only as manganese powder absorbed is harmful, but manganese in stainless steel is alloy, difficult to be dissolved, very small amount of dissolved is harmless to human body basically.

WhatsApp)

WhatsApp)