Blair Strip Steel | New Castle, PA

Blair Strip Steel is a heavy gauge specialty strip mill located in New Castle, PA the most trusted producer of Global and North American specialty strip steels .

WhatsApp)

WhatsApp)

Blair Strip Steel is a heavy gauge specialty strip mill located in New Castle, PA the most trusted producer of Global and North American specialty strip steels .

Our leadership in delivering stainless steel sheet, specialty plate, and specialty coil is backed by one of the world''s most powerful mills, our Hot Rolling and Processing Facility (HRPF) near Pittsburgh, Pennsylvania. ... ATI Flat Rolled Products. Call . Contact ATI Online.

HOT STRIP MILL — HIGHEST PERFORMANCE FOR NEW AND EXISTING STEEL MILLS The demand for hot rolled strip is growing in multiple ways. To remain competitive, new and existing mills must meet this challenge in the best possible way. The production of hot strip is a key element of steel .

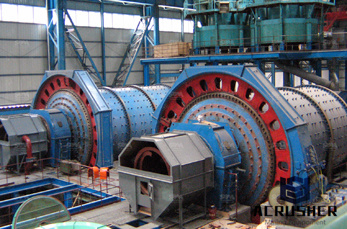

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (Ibeams, angle stock, channel stock), bar stock, and rails. Most steel mills have rolling mill divisions that convert the semifinished casting products into finished products.

In the rolling mill technology product range, hpl Group designs and manufactures both new rolling mill and retrofitting technology for all ferrous and nonferrous metals. ... Our product range covers rolling mills from 150 mm to 800 mm strip width at a strip thickness from to 8 mm.

A 300mmwide strip 25mm thick is fed through a rolling mill with two powered rolls each of radius = 250 mm. The work thickness is to be reduced to 22 mm in one pass at a roll speed of 50 rev/min. The work material has a flow curve defined by K = 275 MPa and n .

Typical processing strip thickness: 0,15 to 8 mm Typical coil weight: 5 to 15 Ton; Skin Pass Mills Four High unidirectional Skin Pass Mills. INCO manufacture either skin pass mills for Hot Rolled black material or for Cold Rolled or Galvanized material. Mills can be complete or be installed in continuous treatment line. Strip width up to 1800 mm.

In the late 1800''s, when iron production gave way to steel production, Blair moved to the cold side of the new industry as a light gauge cold rolled strip mill, making precision steel strip for cash registers, typewriters and adding machines.

Hot Rolling Technology ... In hotrolling of steel, the temperature in the ultimate finishing stand varies from 8500 C – 9000 C, ... The layout of a rolling mill varies, from a simple single stand mill to several stands positioned either side by side or in a line.

Until now. Advances in production technology and materials science, particularly for new types of hightech steel, mean that Bessemer''s "twinroll" idea is being taken up successfully.

One Pass Cold Rolled Strip. One pass coldrolled strip is hotrolled steel that is gaugecorrected through rolling to produce precision tolerances. This innovative product is produced with milder cold reductions than that of cold rolled strip and is ideal for unexposed applications and applications that do not demand a high degree of formability.

As a professional China steel strip rolling mill units manufacturer and equipped with a famous factory and plant, as well as providing with steel strip rolling mill units for sale, welcome to check the process and layout with Xi''an Hani New Energy and Technology Co.,Ltd.

continuous processing for cold strip rolling. Development of endless hot strip rolling When rolling steel sheets on hot strip mills, to avoid a temperature drop in the rolled material, it is necessary to pass it through finishing mill stands at high speeds, which makes the rolling of the head and

The 3rd generation of the wiping system DMS Wiper SCP enhances the performance of rolling mills by enabling higher rolling speed and reduced maintenance downtime. This advanced system offers the best available technology in terms of highest rolling speed, higher wiping efficiency and .

technology for producing hot strip on a minimill scale. It is a patented process that combines a medium thickness slab caster (thicknesses of 90 – 150 mm) with a Steckeltype rolling mill to produce a hot strip facility with modest capital expenditure. So, if you are a minimill producer, you can adopt this technology

The AIST 2015 North American Hot Strip Mill Roundup was reviewed, which gives an overview of capabilities and equipment. The roundup was published in the November 2015 issue of Iron Steel Technology. Hot Rolling Fundamentals — A Practical Training Seminar was reviewed. The conference will be held 21–25 February 2016 in Birmingham, Ala., USA.

Cold Finished Flat Bar Steel. Cold rolled bar steel is processed more than hot rolled bar steel. It is cold finished in various ways (such as by turning, cold drawing, grinding, polishing, etc.) to eliminate surface imperfections, increase the steel''s tensile strength, size the steel .

Xtek has manufactured Forged and Specialty Rolls for over 70 years. Special steel chemistries, coupled with unique and proprietary heat treating methods, have led to products with superior metallurgical properties and are the reason that Xtek is one of the leading suppliers of Forged and Specialty Rolls for many rolling mill applications.

Primetals Technologies is the only supplier in the world that can supply a complete endless rolling system, and five hot strip mills are under operation with our endless rolling technology, with remarkable accomplishments. Primetals Technologies offers, in connection with the above, the following proven technologies for the customer.

KELK Introduces New ACCUBAND Strip Width Gage for Cold Rolling Steel Mills and Processing Lines ... sensors for cold rolling mills and processing lines." The new ACCUBAND C775FF joins KELK''s ...

NEW ROLLING METHOD OF REVERSING COLD ROLLING MILL Authors Name and Affiliations Yohei Kannaka, Tanehiro Kikkawa / Rolling Mill Department, Technology Engineering Division, JP Steel Plantech Co. / Yokohama, Japan Contact data ... the development of a new rolling method (ZoomMill™, or zerooriented offgauge

Compact Strip Production (CSP) is a novel technology developed in 1980s for castinghotrolling of thin slabs. It is new technological innovation following converter steelmaking and continuous casting technology in steel industry. This technology provides a more compact line and a more simple procedure as compared with the traditional hot ...

Steel Steel Forming of steel: Forming processes convert solidified steel into products useful for the fabricating and construction industries. The objectives are to obtain a desired shape, to improve cast steel''s physical properties (which are not suitable for most applications), and to produce a surface suitable for a specific use.

WhatsApp)

WhatsApp)